Pebble Shower Floors Precautionary Letter approved by NTCA Technical Committee – January 2022

At the last meeting of the NTCA Technical Committee at Total Solutions Plus in Jacksonville, Fla., last October, the NTCA Pebble Shower Floors Precautionary Letter was approved for insertion in the upcoming NTCA Reference Manual.

At the last meeting of the NTCA Technical Committee at Total Solutions Plus in Jacksonville, Fla., last October, the NTCA Pebble Shower Floors Precautionary Letter was approved for insertion in the upcoming NTCA Reference Manual.

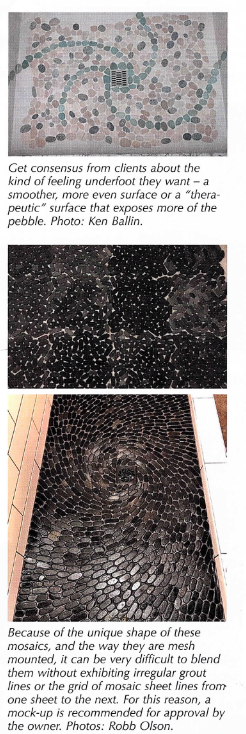

Jim Whitfield FCSI, CCPR, LEED AP, Director of Technical Services I for MAPEI, headed up this committee, which also included Dirk Sullivan, Hawthorne Tile; Dan Lambert, Lambert Tile & Stone; Dave Rogers, LATICRETE, and Joe Kerber, KerberTile Marble & Stone. This particular paper has been in the works for about a year and a half and through several revisions. Whitfield said it stresses the importance of having a quality tile installer do the work, and wrangle with irregular shapes on mesh backing, the specter of sheet lines that can often occur, and getting consensus from clients about the kind of feeling underfoot they want -a smoother, more even surface or a “therapeutic” surface that exposes more of the pebble.

This letter will appear in its entirety here, so TileLetter readers are getting a preview of the document. The next meeting of the NTCA Technical Committee will be January 31, 2022 at The International Surfaces Expo, in Las Vegas, Nevada. It is open to the public and participation among -Jall levels of the industry is encouraged.

This letter will appear in its entirety here, so TileLetter readers are getting a preview of the document. The next meeting of the NTCA Technical Committee will be January 31, 2022 at The International Surfaces Expo, in Las Vegas, Nevada. It is open to the public and participation among -Jall levels of the industry is encouraged.

Pebble Shower Floors Precautionary Letter

The tile and stone industry has benefited from the popularity and growth of pebble mosaic and other irregular shapes of river rock, marble, glass, and stone. While this outdoorsy look is trendy and different, it can be a very challenging to the tile contractor installing it.

The surface of these mosaics can be flat or rounded, much like those found in nature. Because of the unique shape of these mosaics, and the way they are mesh mounted, it can be very difficult to blend them without exhibiting irregular grout lines or the grid of mosaic sheet lines from one sheet to the next. For this reason, a mock-up is recommended for approval by the owner. When the mock-up is not acceptable, some installers cut the mesh the mosaics are mounted on or frequently remove stones or tiles from the sheets to blend them together and not be inhibited by the mesh mounting. Most would agree, the result is better looking but also very time consuming and costly. ‘

The surface of these mosaics can be flat or rounded, much like those found in nature. Because of the unique shape of these mosaics, and the way they are mesh mounted, it can be very difficult to blend them without exhibiting irregular grout lines or the grid of mosaic sheet lines from one sheet to the next. For this reason, a mock-up is recommended for approval by the owner. When the mock-up is not acceptable, some installers cut the mesh the mosaics are mounted on or frequently remove stones or tiles from the sheets to blend them together and not be inhibited by the mesh mounting. Most would agree, the result is better looking but also very time consuming and costly. ‘

Installation Considerations:

When installing river rock or stone pebble mosaics over a foam-based shower pan you should consult the manufacturer to see if these types of material are acceptable regarding point loading.

- The plumbing code in most jurisdictions requires a minimum slope to drain of 1/4″ minimum from the farthest point per 12″ of run, maximum 1/2″. To facilitate better. water flow to the drain around the pebbles and irregular shapes, additional slope may be needed. Consult your local building code authority for maximum allowable slope.

- For proper adhesion, the bond coat of thin-set mortar must be applied thicker than normal to make contact with the irregular shape of the stone while at the same time not come up too high into the joint. To do this, use the flat side of the trowel to collapse the mortar ridges to achieve a smooth consistent setting bed. For additional information refer to the NTCA’s “Trowel and Error” video.

- Normally, the shower floor tile is installed first fol lowed by the wall tile. When using pebbles, this will require a significant amountof time and installer expertise to scribe the bottom row of wall tile to the pebbles and will increase the cost of installation. Alternately, the wall tile may be installed first with the pebbles cut to the wall with the appropriate and consistent joint width. Either way, the installation of the 100% silicone sealant can be a challenge, which again,

requires more time and skilled labor. - Care must be taken to arrange and cut edges of the pebble or stone at .d.rains, curbs, and any other terminations to avoid sharp exposed edges.

Grout Considerations:

The irregular depth and width of the grout joint makes estimating how much grout will be needed difficult.

Frequently in these types of installations grout joints can exceed a 1/2″ in width and the same in depth. In addition, since the grout widths are irregular, they can be difficult to grout with grouts that remain soft during installation and clean up, like ready-to-use grouts or epoxies. These installations must be approved by the grout manufacturer and should only be installed by a professional familiar with these grouts.

The irregular surface makes cleaning during installation of the grout, very time consuming and often inconsistent. When grouting these types of materials depending on how full you leave the joint or how much is removed, you can yield a different appearance and feel.

When the end user is looking for for a lower grout joint exposing more of the pebble for a therapeutic feel, they need to be aware for the potential of pooling water between the stones, leading to discoloration and potential mold / mildew. The river rock or stone pebble mosaic can be an attractive look, but many find them uncomfortable to walk or stand

on and are looking for a fuller looking joint and not exposing as much of the pebble.

The grout can also take a longer time to dry out, due to the mass of grout between tiles. This can delay the return to use.

Stone mosaic tile could be presealed to ease the cleaning and reduce potential for staining.

While this popular trendy look continues to grow, the irregular shapes of river rock, marble, glass, and stone present some challenges, so planning and mock ups can be critical for success and the customer’s approval. For your

best opportunity for success, these mosaics should be installed by an experienced professional with knowledge of these installations, the best materials to use and how to get them to drain properly. TL